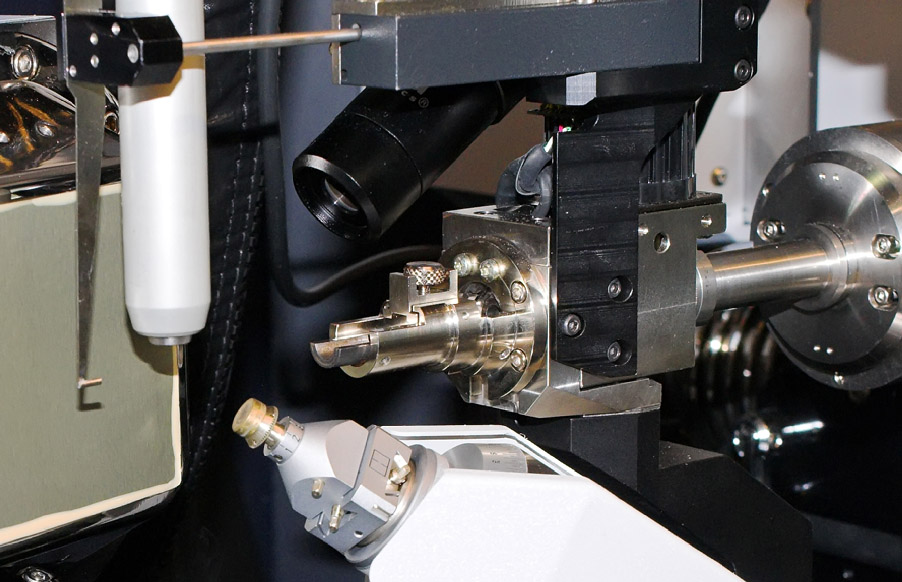

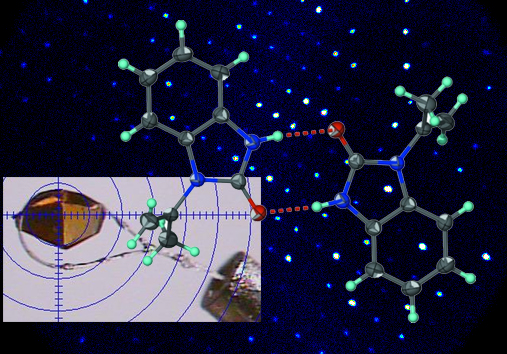

Diffraction data will be collected at various X-Ray Diffraction Facilities in the Boston area with which The Structure Factory, LLC is doing business. The crystal will be mounted on a MiTeGen™ loop in Paratone oil at low temperatures. Temperature of choice is usually 100K, unless specified otherwise by you or unless a destructive low-temperature phase transition or other considerations require data collection at a higher temperature. In principle, temperatures between 90K and 500K are possible. All X-Ray Diffraction Facilities used by The Structure Factory, LLC are equipped with modern and versatile Bruker diffractometers that allow collecting complete and highly redundant datasets in any given Laue class meeting or exceeding the International Union of Crystallography requirements for good data. These diffractometers are coupled to extraordinarily sensitive Bruker APEX and APEX2 CCD detectors that give rise to high-resolution data even on very small crystals (down to 10µm).

Data collection will be performed using Mo or Cu radiation, depending on the requirements of the project. Mo radiation gives rise to higher resolution data and is the preferred wavelength for most routine samples. Cu radiation is required to obtain anomalous signal from light-atom structures (at least one oxygen for every 10 carbon / nitrogen atoms is recommended) and is sometimes needed to obtain a good diffraction pattern from very small crystals.

The Structure Factory, LLC uses state-of-the-art diffraction equipment that allows collecting high-quality datasets in any given Laue class.

The Structure Factory, LLC uses state-of-the-art diffraction equipment that allows collecting high-quality datasets in any given Laue class.  Services offered by The Structure Factory, LLC include crystallization, full structure determination, training and expert witness services.

Services offered by The Structure Factory, LLC include crystallization, full structure determination, training and expert witness services.  Our pledge to you: The Structure Factory, LLC strives to always determine the best structure possible from any given sample.

Our pledge to you: The Structure Factory, LLC strives to always determine the best structure possible from any given sample.